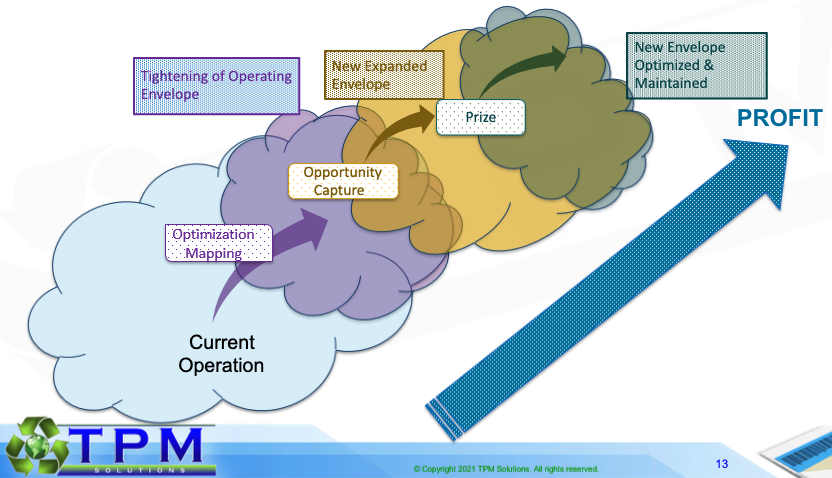

Comprehensive solution comprising an online, advisory, plant-wide Prize BML™ (Priority Optimizer - Beyond Machine Learning) optimizer that presents optimum targets for key monitoring points based on current feedstock properties, latest market prices and plant constraints. During mapping of the key monitoring points opportunities to improve margin are identified and captured prior to deployment of the plant wide optimizer.

Why do companies use TPM Edge?

Plant-wide, multi-unit, real-time Optimization

Business Issue: There is a significant gap between Actual and Optimal performance of the process across the entire site.

Financial Impact: $ 5 MM to $ 20 MM / year margin leakage for a medium sized Refinery or Petrochemical complex.

Solution: TPM Edge: A comprehensive program and application to enhance and sustain optimal complex-wide operational performance (including energy and GHG emissions management).

Experience: Implemented at over 25 plants globally

Benefits delivered: Exceed 5 times annual subscription costs